Kansas City

|

Dry Ice Blasting Applications

Freezer Ice RemovalClean up those slick floors, reduce falls, and eliminate freezer down-time with our waterless cleaning method!

Forklift aisles cleaned up, free of ice, and safe once again for pedestrians and material handling machinery!

|

Paint RemovalKyle examining the wall to see the best way to remove the paint efficiently.

Restore those beautiful building walls or art work with the gentle power of dry ice blasting.

|

Robotic Welder CleaningNeed to clean up that robotic welder but can't afford the down time for dis-assembly or water proofing? Call us!

Clean up that weld slag and debris and let your quality welds increase and repair and scrap bills decrease!

|

Power Generation EquipmentNon-conductive dry ice is the perfect cleaning agent for sensitive electronic equipment cleaning. More downtime means less strain on other machines and lower repair costs. Great way to keep productivity up while still doing necessary maintenance cleanings!

|

Food Processing EqiupmentDry ice is free of chemical residues and can actually reduce pathogens when used on cleaning food processing equipment. Less time required to dis-assemble equipment and it is ready to start up again almost immediately after cleaning!

|

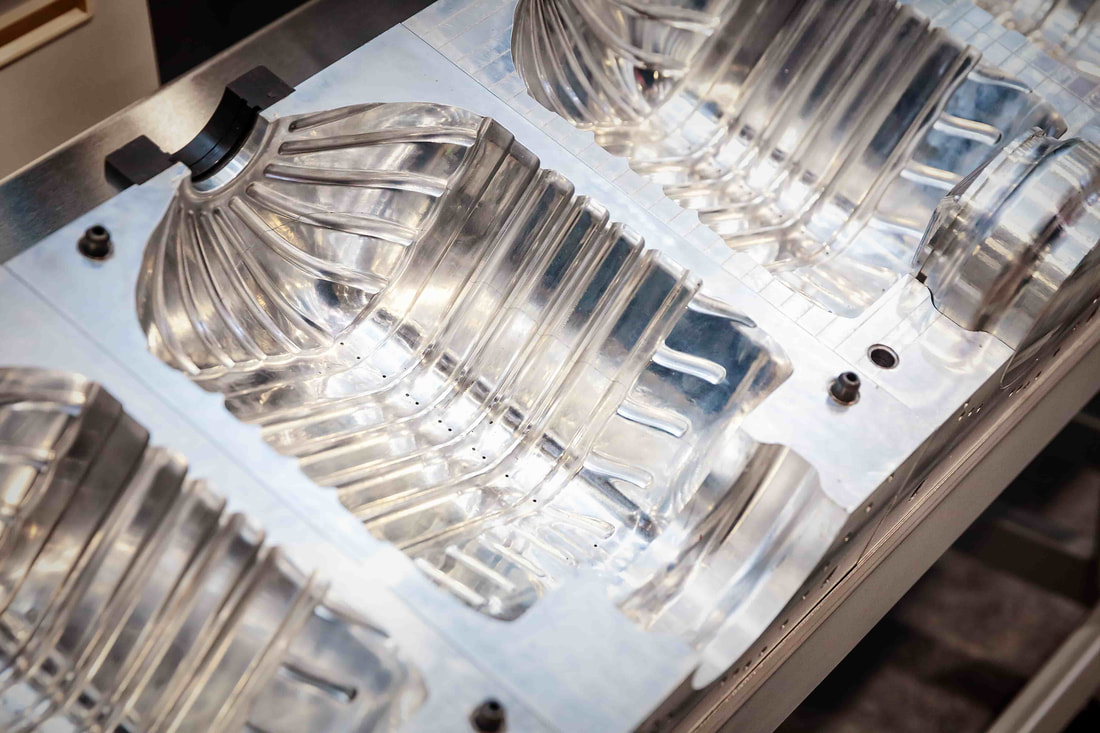

Plastic & Resin Injection Mold CleaningDry ice blasting won't rust metal molds, won't leave behind chemical residues, and can increase quality of pours. Easier cleanup and less downtime means better production output and higher quality delights customers!

|

Industrial Machine Maintenance Cleaning Programs

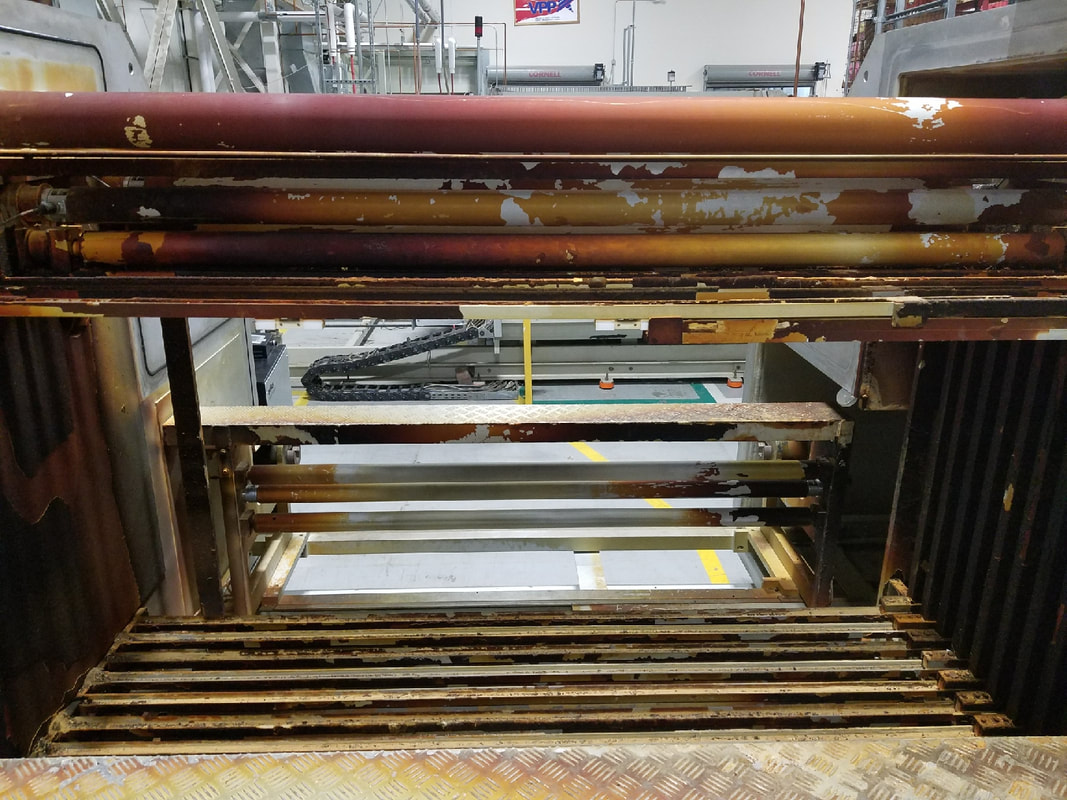

BeforeThis industrial machine was covered in months or years of residue from constant use. Lower quality products, increased downtime, and more costly repairs result from lack of preventive maintenance cleanings. Dry ice blast cleaning allows for cleaning of these items with little or no disassembly and minimal down-time.

|

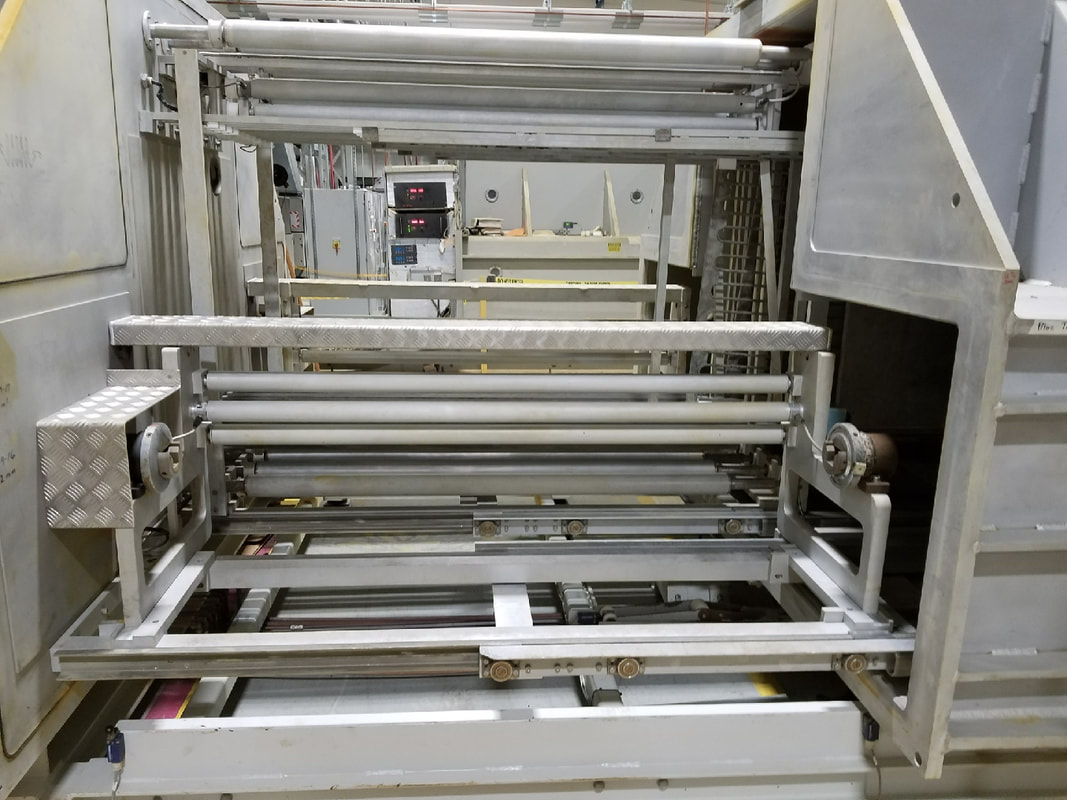

AfterAfter dry ice blast cleaning this machine, residues are gone and the machine looks great. All the moving parts are able to work as designed without being thrown out of balance from debris and repairs and down-time become minimal. This also presents a better image to potential clients visiting and to employees that need to use the machines.

|